Industrial assemblies depend heavily on components that hold structures, machinery, and systems together under extreme conditions. Among these components, Connection Fasteners play a crucial role in ensuring mechanical stability and long-term durability.As industrial applications become more complex ranging from heavy engineering and infrastructure to energy and manufacturing the demand for advanced connection fasteners has grown significantly.

With support from trusted solution providers like ES HAJI & CO, industries are increasingly adopting innovative fastening technologies that meet modern performance, safety, and efficiency standards.

These fasteners are no longer simple mechanical elements; they are engineered solutions designed to withstand high loads, vibrations, corrosion, and environmental stress.

Understanding Connection Fasteners

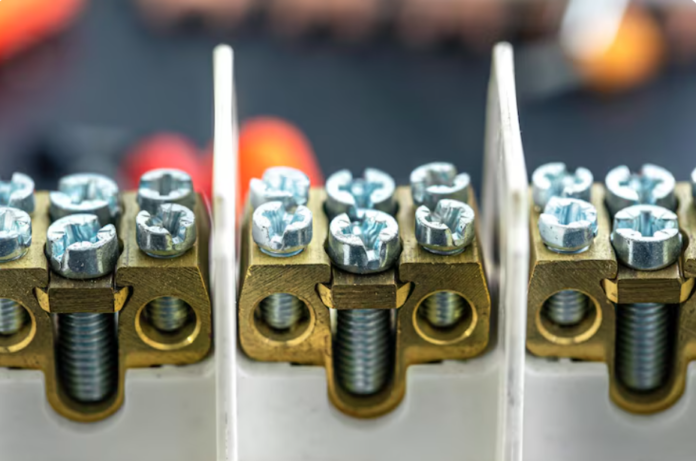

Connection fasteners are mechanical components used to join two or more parts securely. They ensure that structures and machines remain stable, aligned, and functional during operation. Common types of connection fasteners include:

- Bolts and nuts

- Screws and studs

- Anchors and pins

- Washers and locking mechanisms

These fasteners are widely used in industries such as construction, oil and gas, power generation, automotive, heavy machinery, and manufacturing. Their performance directly impacts safety, productivity, and maintenance costs.

Why Innovation in Fasteners Matters

Traditional fasteners served basic purposes, but modern industrial requirements demand more advanced solutions. Innovation in fastener technology addresses several critical challenges:

- Higher load-bearing capacity

- Resistance to vibration and fatigue

- Corrosion protection in harsh environments

- Faster and safer installation

- Reduced maintenance requirements

Innovative connection fasteners help industries improve operational efficiency while meeting stringent safety and compliance standards.

Role of Foundation Bolts in Industrial Assemblies

In large-scale industrial and infrastructure projects, Foundation Bolts play a critical role as specialized connection fasteners. These bolts anchor structural elements, machinery, and steel frameworks securely to concrete foundations.

Foundation bolts are essential for:

- Structural stability in buildings and industrial plants

- Securing heavy machinery and equipment

- Load transfer between structures and foundations

- Resistance against seismic and dynamic forces

Innovations in foundation bolt design now include higher tensile strength, corrosion-resistant coatings, and customized dimensions for specific project requirements. These advancements enhance safety and durability in demanding industrial environments.

Material Advancements in Connection Fasteners

One of the most significant innovations in fastener technology is the use of advanced materials. Modern fasteners are manufactured using high-performance alloys and treated steels that provide exceptional strength and durability.

Common material advancements include:

- High-tensile carbon steel for heavy-load applications

- Steel for corrosion resistance

- Alloy steel for extreme pressure and temperature conditions

- Surface coatings such as galvanization and anti-corrosion treatments

These material improvements ensure that connection fasteners perform reliably even in aggressive industrial environments.

Corrosion-Resistant and Coated Fasteners

Industrial fasteners are often exposed to moisture, chemicals, heat, and outdoor conditions. To address this, modern fasteners are treated with protective coatings that extend their service life.

Common protective solutions include:

- Hot-dip galvanizing

- Zinc and epoxy coatings

- Anti-corrosion chemical treatments

These innovations reduce maintenance needs and prevent premature failure, especially in coastal, chemical, and outdoor industrial installations.

Fasteners for Automation and Modern Machinery

As industries adopt automation and advanced machinery, fastening solutions must adapt accordingly. Automated systems require fasteners that provide precise alignment and consistent performance.

Innovative connection fasteners support automation by:

- Ensuring repeatable installation accuracy

- Reducing downtime during maintenance

- Supporting high-speed and continuous operations

These fasteners are critical for robotics, automated production lines, and advanced manufacturing systems.

Installation Efficiency and Safety Improvements

Modern fasteners are designed not only for performance but also for ease of installation. Improved designs help reduce installation time, labor costs, and workplace hazards.

Key improvements include:

- Simplified fastening mechanisms

- Reduced torque requirements

- Better grip and handling features

These innovations enhance worker safety while improving project efficiency.

Industries Benefiting from Innovative Fasteners

Innovative connection fasteners are widely used across multiple industries:

- Construction and infrastructure

- Oil and gas

- Power generation

- Heavy engineering

- Automotive and manufacturing

Each of these sectors relies on advanced fastening solutions to ensure safety, performance, and compliance with regulations.

Future Trends in Connection Fasteners

The future of connection fasteners will continue to focus on:

- Smarter locking mechanisms

- Advanced materials and coatings

- Digital integration with engineering systems

- Enhanced safety and compliance features

As industrial systems grow more complex, fastening technologies will evolve to meet new challenges and performance expectations.

Connection fasteners are no longer simple mechanical components; they are engineered solutions that directly impact industrial safety, efficiency, and durability. With ongoing innovation in materials, design, and manufacturing, modern fasteners are meeting the demands of high-performance industrial applications.